Premium Plunger Lift Equipment

The Widest Parts Selection in Alberta!

We proudly offer the industry’s widest and most diverse line of Plunger Lift Equipment & Servicing for liquid loading Gas wells or Gassy Oil wells that flow **.

Our wide selection of available plunger lift equipment and parts include:

- Virtually every possible style of plunger

- Heavy duty bottom hole springs

- Dual-stage systems

- Velocity/flow tubes

- Lubricators

- Sensors, controllers & more

And best of all, our parts & components are all Alberta‑made – ensuring reliability, quality & long-term performance. (No offshore knock-offs here! )

** Even for former Premier Integrated Technologies (PIT) designs!

Do You Need Plunger Lift Servicing?

With decades of industry & well experience, we can service and repair almost all types of Plunger Lift equipment. In fact, we regularly help our clients find increased production for minimal costs. Using our advanced high-tech testing and analysis services, we can make recommendations for those key changes needed to optimize each of your wells.

And because of our years of expertise, we’ve seen for ourselves that preventative maintenance and timely replacement of worn parts is a critical part of keeping your plunger lift operating costs low – so we are there with you every step of the way.

From custom plunger lift designs to full plunger installs to replacement parts and servicing – our expert design + deep inventory supports your seamless operations.

We are your cradle-to-grave production partner in plunger lift – we do it all and have it all.

Contact us below to learn more.

Parts

Quick tip: When choosing a plunger, the type of plunger depends on the well’s production volume, and the type of production. However, it can also be influenced by the production facilities, line pressures, and access to location. Not sure what you need? Just ask our experts!

Check out some of our most popular parts below:

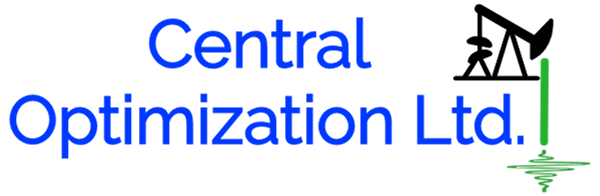

Cleanout Plungers

Highlights & Benefits:

- Proven solid design for strength and durability using L-80 NACE spec material

- Lower efficiency but lower cost and higher longevity in the long term over brush plunger.

- Opposing cutting surfaces and specially designed groove spacing improves turbulence and cleaning on both fall and return arrivals.

- Flighting on the bottom section promotes a spinning action to aid in even wear in deviated wells.

Where & Why To Use:

- Excellent for paraffin, sand, scale, solids removal

- In deviated wells as helps even out wear

Solid or Bar Stock Plungers

Highlights & Benefits:

- The Solid plunger is a strong, simple, and usually low cost product.

- Bar stock plungers are the least efficient due to ridged seal design. This plunger maximum O.D can only be made to tubing drift.

- Built in many different lengths, weights, materials, & spacings for different well characteristics.

Where & Why To Use:

- Paraffin, asphalten, and wells with a thick emulsion are good candidates for the solid plunger

- Remote wells, or rarely inspected wells are also good candidates

Brush Seal Plungers

Highlights & Benefits:

- The Brush plunger is a very efficient seal design when new, as efficiency can drop quickly with plunger operation.

- Seal is efficient but being made of Nylon materials it is affected by heat and aromatics in the well bore.

- Seal can wear out quickly BUT some wells will only run with Brush plunger

- The Brush seal is wrapped directly to the plunger body with stainless wire, or attached to an insert and slid over the plunger mandrel then held in place by a lock assembly.

Where & Why To Use:

- Commonly used when a well produces solids, like frac or formation sand.

- Not to use in wells that produce Heavy Paraffin or Asphalten.

- Low rate wells often need the high seal efficiency to work

Pad & Dual Pad Plungers

Highlights & Benefits:

- The Pad Plunger is a very efficient seal design. Because the pads are able to adjust/expand to the max tubing I.D., the plunger will maintain a consistent seal while it is traveling up the tubing.

Where & Why To Use:

- Wells that make a clean fluid with NO SAND or SOLIDS

- Wells that have tight spots in the tubing or even downhole reduced ID nipples

skirted Plungers

Highlights & Benefits:

- New Improved pad design from high tech flow modeling.

- Increased seal and overlapping pad design reduces gas and liquids bypass as well as improves pad strength.

- Travels through tubing sleeves and profiles in tubing.

Where & Why To Use:

- Low rate wells with clean fluids (NO sand or solids)

Combination Plungers

Highlights & Benefits:

- All the same benefits as the padded plunger in vertical but has a brush or solid section to seal better in the horizontal sections of the tubing string for maximum efficiency when pads flatten out and bypass.

Where & Why To Use:

- Horizontal wells

- When a better seal is needed to come off bottom at deviated angles

“Test Pilot” Plungers

Highlights & Benefits:

- Designed for use as a trial plunger for wells being considered for plunger operation or to prove economics.

- Temporary install to test a well

Where & Why To Use:

- Used in horizontal applications with high solids formation to eliminate downhole restrictions and BHSA damage from solids washing.

- Highly deviated bottomhole landing in tubing where BH Spring cannot be landed

Rapid / Quick Drop Plungers

Highlights & Benefits:

- Intermediate step between Pacemaker and Conventional Plunger Lift

- Designed to run with minimal shut-in time

- Runs with existing equipment on surface and subsurface

Where & Why To Use:

- Application for wells that need a high number of trips to remain unloaded

- Higher rate wells that are > 60% of critical rate when unloaded

- Where wellhead “gap” issues or client does not want a 2 piece plunger

Fastfall/CleanOut Plungers

Highlights & Benefits:

- Lowers off time and increases flow time, thus higher production rates are possible.

- This particular type of CleanOut FastFall also handles sand and wax in the well.

- Very robust and well adapted plunger for many well types

Where & Why To Use:

- Wells with sand and wax concerns

- Ideal for many well types

Pacemaker Plungers (2pc)

Highlights & Benefits:

- The Pacemaker Plunger system operates very differently than a Conventional Plunger system.

- Pacemakers are a Velocity plunger

- To surface the plunger & fluid, a velocity plunger uses the energy directly from the formation.

- Does not need to shut in well to build or store energy.

Where & Why To Use:

- Higher rate wells that flow >60% of critical rate when unloaded

- Where our Plunger Calculator shows a Conventional plunger won’t lift all the potential fluids per well

- Runs excellent with wellhead compression (supplies nearly constant gas flow)

High-Impact Bottom Hole Springs

Highlights & Benefits:

- Old BHS had a compression rate of 265 psi/in2.

- This new style is ~3 inches less of Inconel spring coil, but has more travel per square inch at 310 psi/in2.

- This is accomplished by adding the Bellville washer stack in the cage.

- Giving the spring a total compression rating of 3100 psi/in2

- The spring is designed to engage the washer pack at 70% of total compression.

- Various materials options for SOUR/salts etc

Various Alternative Bottom Hole Springs

Highlights:

- Econo sweet springs for lower cost/low rate wells

- Extreme SOUR BH springs available

- DUAL STAGE Plunger system “centre of well” Springs available

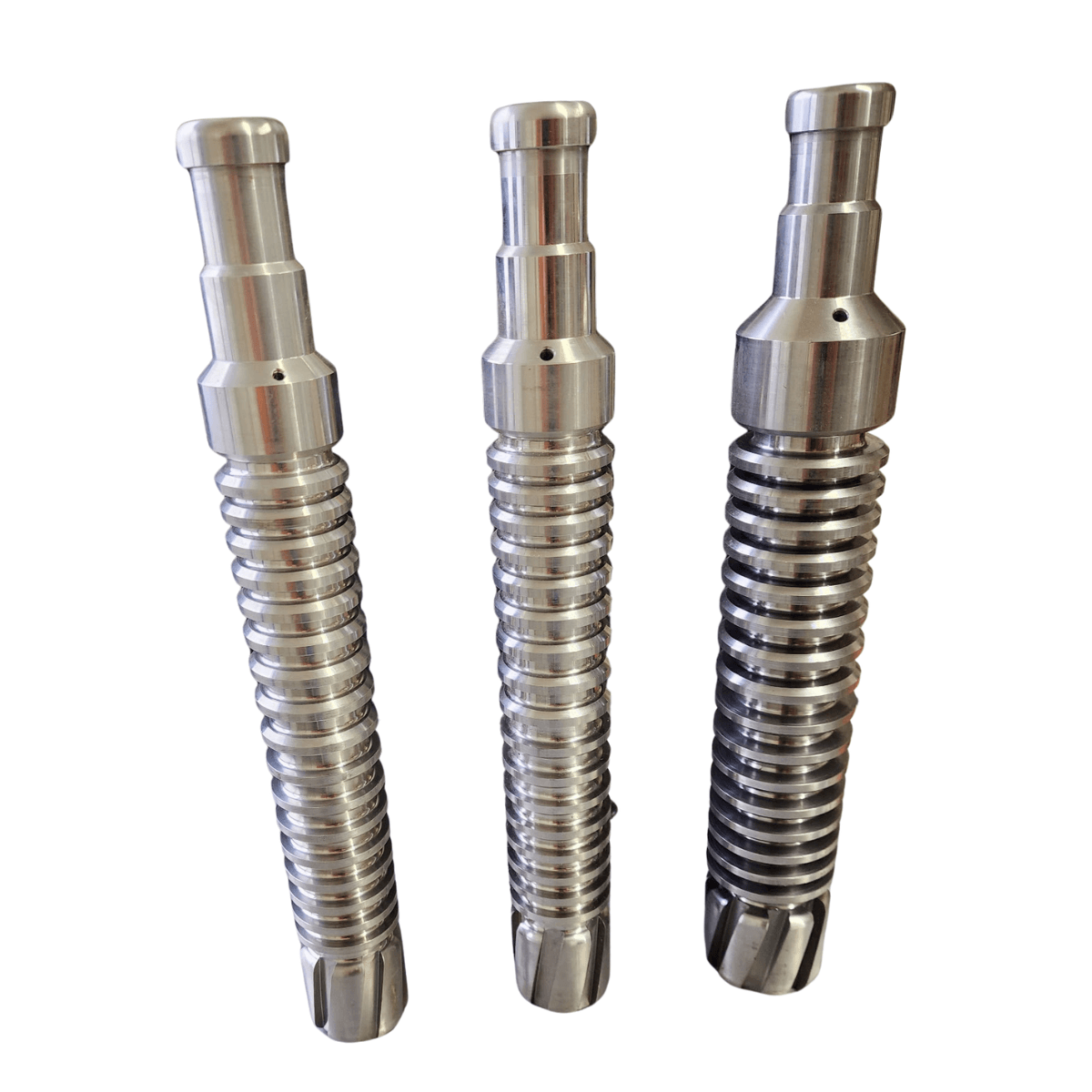

Wide Variety of Plunger Lubricator Options*

*including former Premier Integrated Technologies (PIT) types

Highlights:

- All thread Bowen cap (lowest cost)

- Flanged Base by Dual threaded NPT outlets Bowen Cap

- All Flanged Bowen Cap

- Drop In style (flow-fit and others)

- 2000 psi up to 10,000 psi available

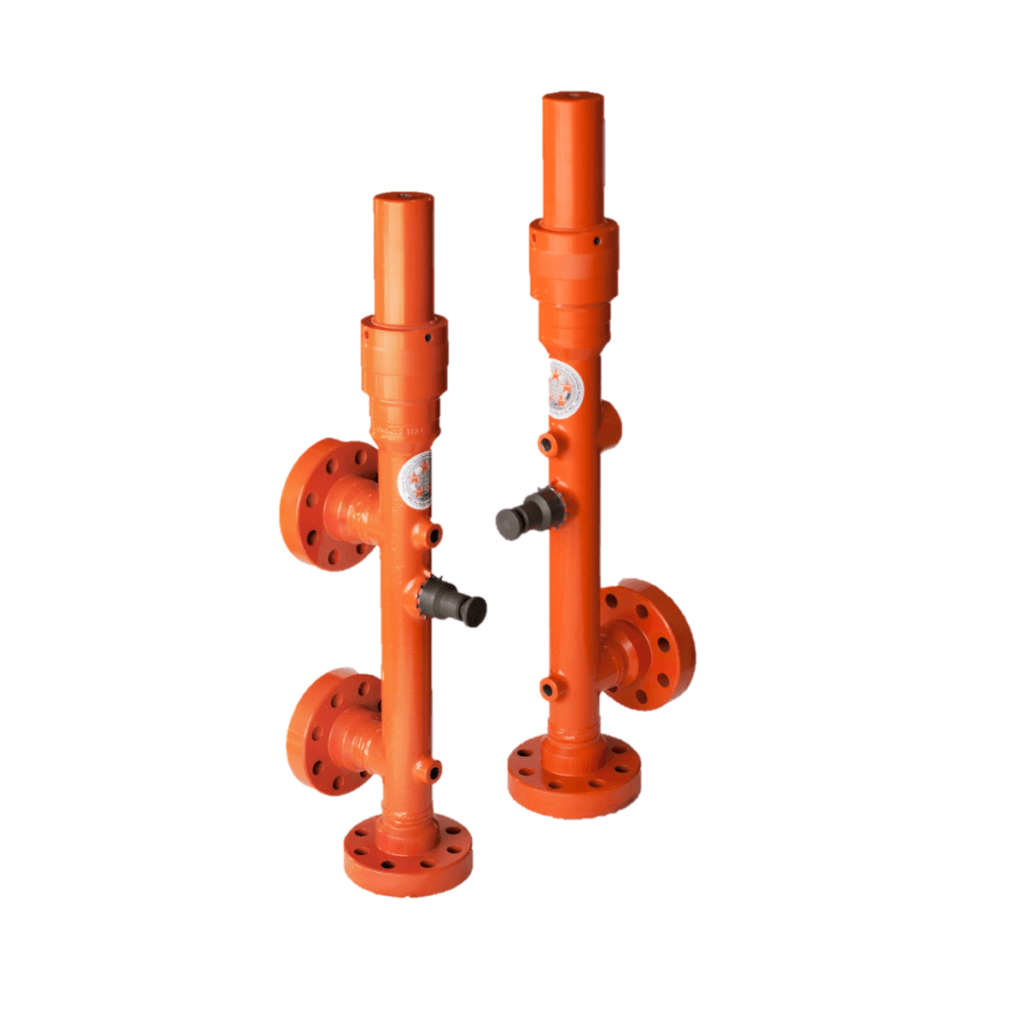

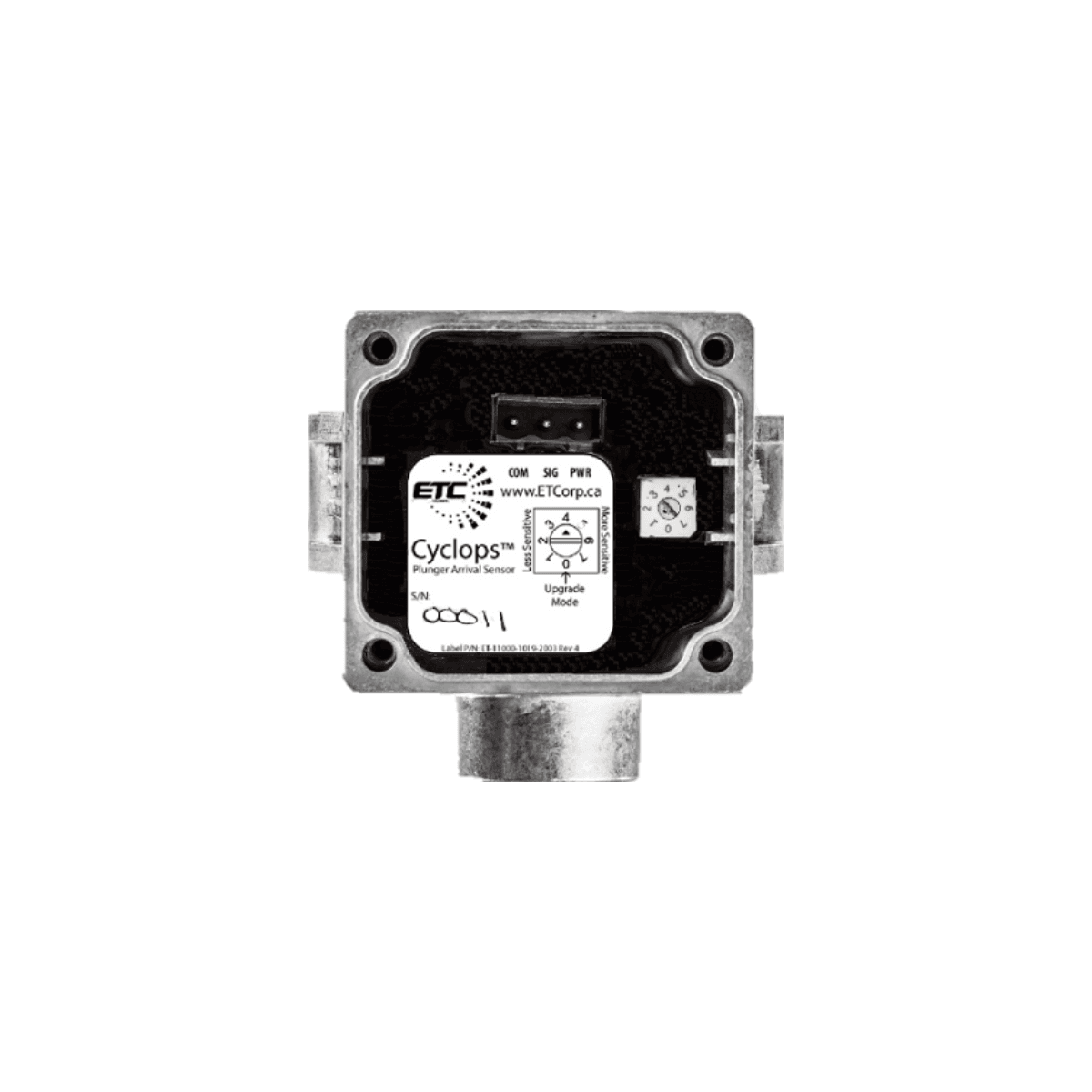

Arrival Sensors & Controllers

Arrival Sensors:

- ETC Cyclops IS & X-proof

- PCS sensors

- TripMate sensors

- WIRELESS options available

Controllers & Replacement Parts:

- Ferguson Beauregard Liquid Lift 3

- PCS 2000

- ETC Alien2 controllers